JellyFish

How to Make one

Here is how I make the JellyFish. If you find an easier or

better way, go for it (and please let me in on your secret method).

FYI I tend to use millimeters as the unit of measure when dealing

with things of this size as I find it easier to think about.

If you prefer inches, feel free to convert. The below shows

how to make the fabric portion of the JellyFish. Be sure to

cut a piece of 3/4 inch schedule 40 PVC pipe about 10 inches long to

use with the JellyFish.

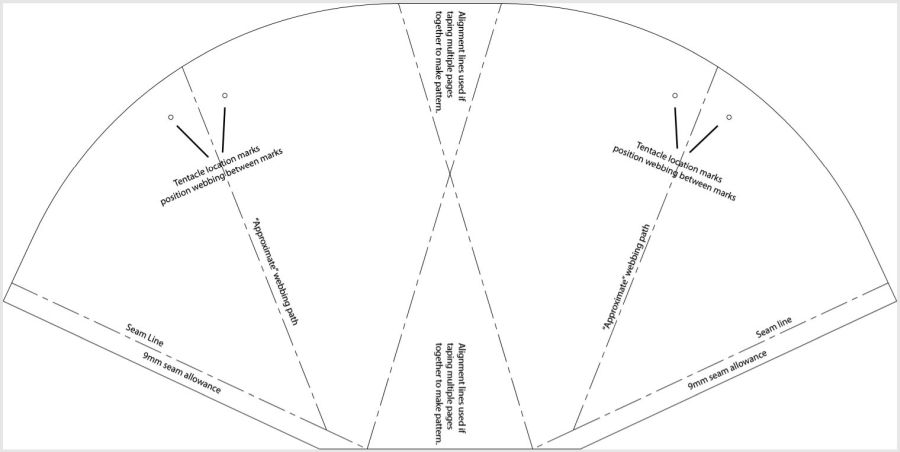

Patterns

The center

lines in the pattern are only to help align the two halves of the pattern if

printed across 2 pages then taped together.

The center

lines in the pattern are only to help align the two halves of the pattern if

printed across 2 pages then taped together.

I have 3 files to help with the pattern.

1. Drawing with a

few dimensions on it to help those who wish to create their own

pattern or modify mine. Not useful for much else.

2. Printable

PDF single page of the pattern. Works well but is larger than a single

piece of letter sized paper so you will need software to tile

it onto multiple pages. If this is something you are already

familiar and comfortable with, go for it.

3. Printable PDF

tiled two page of the pattern. The tiled two

page file is a printable PDF where the pattern has been split

onto 2 pages with an overlap zone. Print out the 2 pages and

carefully align the pages as needed then use clear tape to join them

as one. The words and the diagonal X

lines in the middle help with getting things aligned well.

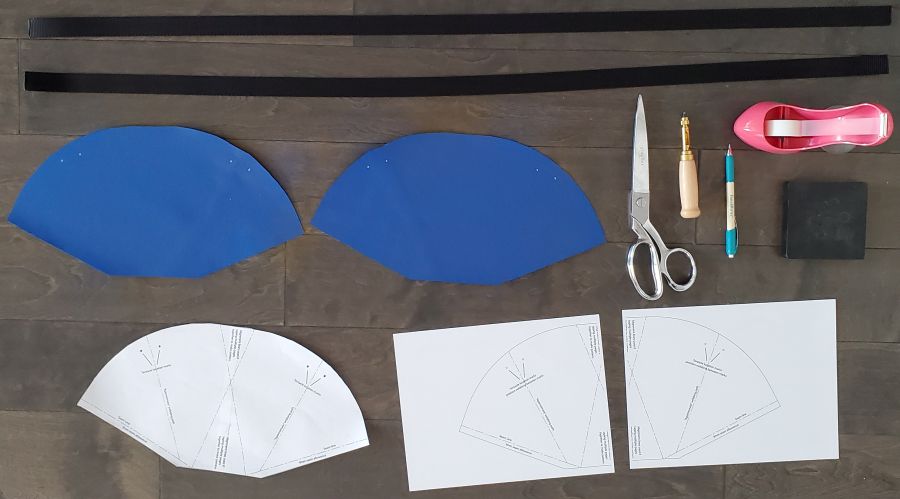

Items used

Two webbing

strips cut to length, two fabric pieces cut using pattern, scissors, screw

hole punch, fabric pencil, clear tape, rubber block, pattern and a two page

version of the pattern that can be tapped together.

Two webbing

strips cut to length, two fabric pieces cut using pattern, scissors, screw

hole punch, fabric pencil, clear tape, rubber block, pattern and a two page

version of the pattern that can be tapped together.

Sewing machine. A home sewing machine is not

going to cut it. For this project an industrial

sewing machine is recommended.

Folder attachment. For adding grosgrain tape (that pretty

black edging added to most sewn gear) you can fold and hold it in

place by hand as you sew but that is a HUGE pain. I use what

is called a folding attachment for my sewing machine that folds and

positions the

grosgrain onto the fabric as I sew. This

makes life super nice! I tried a few cheap ones found online that did

the job but were super finicky. Todd recommended Tennessee

Attachment Company set me up with folder for my specific sewing

machine. Expensive but works very well. If you

decide to contact Tennessee Attachment Company be aware, they have

an old

school feel and you will have a few back and forth conversations

with them before figuring out exactly what you need.

Folder attachment adding grosgrain tape to the JellyFish.

Folder attachment adding grosgrain tape to the JellyFish.

Small items also used. Screw hole punch

(optional but does make hole punching simple). Rubber block as

a backing when using the punch (also optional). Clear tape.

Fabric marking pencil (Fons and Porter pencils work well and can be

scrubbed off later if desired). Scissors.

Thread and stitch count. A very common thread

for sewn gear is #69 (TEX70) multithread bonded nylon thread.

Different manufacturers use different stitches per inch when sewing

gear. There is not set standard making one better than the

other. The general range is 6 to 9 stitches per inch. I

typically use around 7.

Fabric. The JellyFish uses 1000D Cordura

which is a pretty standard fabric for sewn gear that needs to take

abuse.

Grosgrain / binding tape. I get 1

inch grosgrain tape from John Howard Company.

Their

description for it is #30110 1" Nylon Tape #5 Medium Finish Black.

Webbing. I use 1 inch flat nylon webbing from John

Howard Company as it was recommended to me as a good item to use.

Their description for it is #50-0755 1" High Tenacity Nylon Webbing Black

#030. I am not qualified to advise on the best place to get

webbing and will let each person research that. John Howard Company

has a $100 minimum order so you better

need a few things if you use them.

A few notes on webbing.

For sewn goods flat webbing is generally used. One advantage

to using flat webbing for sewn goods is the stitching tends to suck

down into the weave a bit helping protect the threads from abrasion.

It is very difficult to know how strong webbing is by looking at it.

Even if you do know the material used (nylon, polyester, etc.), it is

still extremely difficult to know the quality or breaking strength

of webbing simply by looking at it.

Be careful where you get your webbing for making a JellyFish. You

will be hanging your life on it.

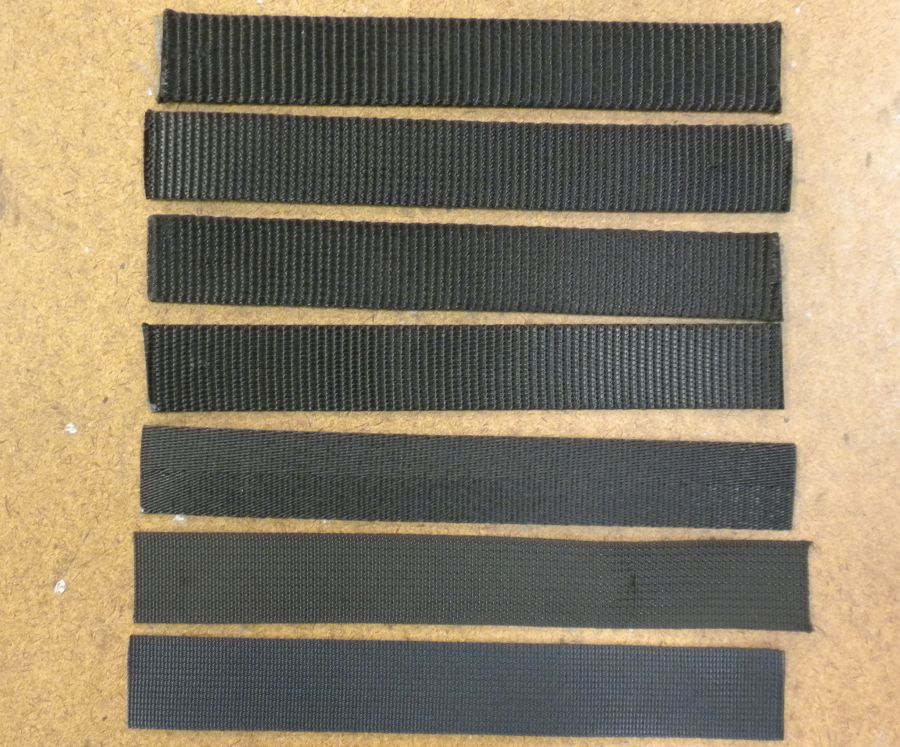

In a

forum post on the Canyon Collective Todd Rentchler of Climb

Sutra / Canyon Werks had this to say... "The multitude of

manufacturers of 'unknown origin' for tubular webbing is scary

enough- but flat-weaves are way worse- there are lots of variations

that yield a wide variety of breaking strengths from quality to junk

that are hard to tell apart." Todd has been in the business for

many years making professional harnesses and various sewn goods for

the movie industry and really knows his stuff. I have been

lucky enough to learn a few tid-bits from him. In that same

forum post he added a picture of 7 pieces of flat webbing, then had this to say about the image: "These are some samples of

webbing we use for manufacturing. The bottom three are easy to

reject as 'not strong enough for a canyon' due to the material being

noticeably thinner. But the top four, ranging in (theoretical)

strength from 6,000 lbs to 3,000 lbs, are VERY difficult to tell

apart."

The top four

pieces of webbing range in (theoretical) strength from

6,000 lbs to 3,000 lbs, are VERY difficult to tell apart.

The top four

pieces of webbing range in (theoretical) strength from

6,000 lbs to 3,000 lbs, are VERY difficult to tell apart.

That is a 3000

lbs difference in strength in the top 4 items, can you tell which is which?

Know what you have before placing your life on it.

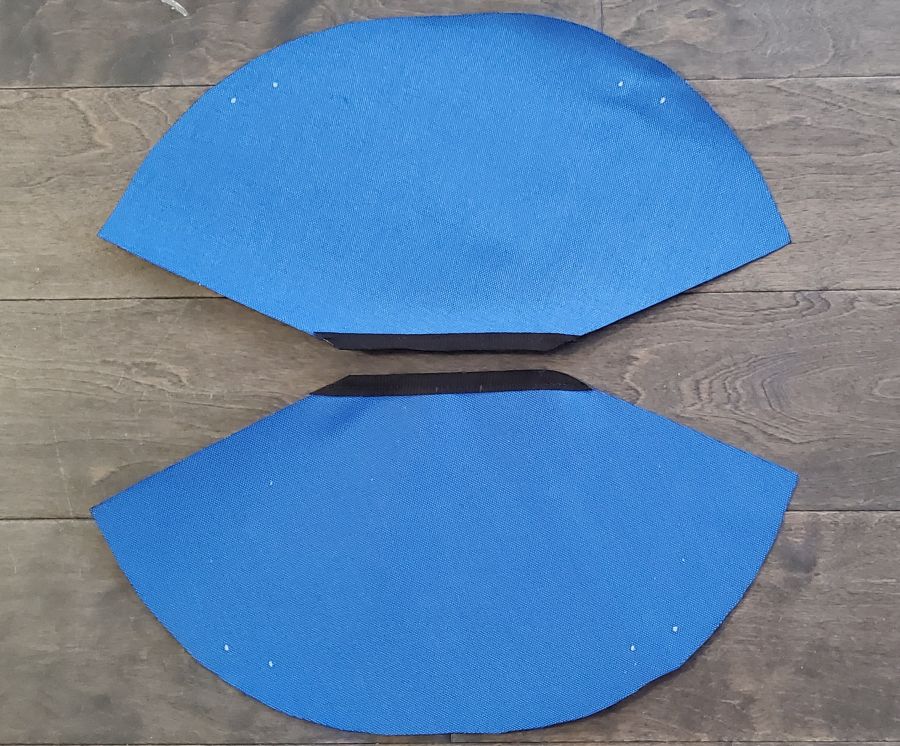

Cut Materials

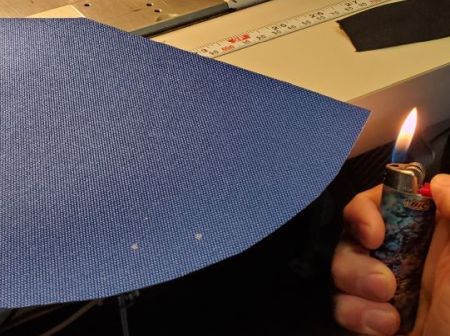

JellyFish Body.

Cut two pieces of 1000D Cordura to make the Body of the

JellyFish. The two pieces are identical so you will need to

use the pattern twice to cut out 2 pieces. Taping the paper

pattern down to the fabric works well to hold it in place while

cutting it out with scissors.

After cutting out the fabric heat seal the edges. I typically

use a lighter and run it along the edge to melt the edges of the

fabric. This is important if you want your sewn good to hold

up over time. If the edges are not heat sealed they can slowly

unravel (getting more and more fuzzy at the edge) until the sewn in

threads simply pull through to the edge. A quick simple

melting of the edge prevents this from happening. Its a small

thing that does matter.

In the pattern are spots to punch holes in the paper pattern

so you can mark the fabric with dots to help align the webbing for

stitching. I use a screw hole punch and a block of rubber to

make it quick and easy to punch out the holes. After cutting

the fabric, keep the paper aligned and use the holes to place marks

on the fabric with fabric pencil. Be sure these marks are made

as they will guide you later.

JellyFish Tentacles. Cut two pieces of 1 inch Nylon

webbing (flat kind not tubular) at 1140mm long. It is not

important for the webbing to be exactly 1140mm long. What is

important is for both pieces of webbing to the same

length.

Heat sealing the ends of the webbing is important just like it is

with the Cordura. If the edged fray and continue to get more

and more fuzzy, the unraveled ends can work their way down to the

stitching and allow the thread to slip out of the end. A

lighter works for this too but more than a quick pass is needed as

the webbing is thicker. I tend to use a propane torch for this

as it makes the job faster.

If the edges

of material are not heat sealed, the edge can fray to the point where stitches

pull right out. Webbing on the left is frayed while webbing on the right

has been heat sealed. Which would you trust more there were stitches a

short distance in from the end?

If the edges

of material are not heat sealed, the edge can fray to the point where stitches

pull right out. Webbing on the left is frayed while webbing on the right

has been heat sealed. Which would you trust more there were stitches a

short distance in from the end? The edges of synthetic fabrics should also be heat sealed. If the edges

fray down to the stitches the seam will fail. Heat seal all edges.

The edges of synthetic fabrics should also be heat sealed. If the edges

fray down to the stitches the seam will fail. Heat seal all edges.

Create JellyFish Body

Add grosgrain tape to the slot edges on both pieces of Cordura.

Add grosgrain tape to the slot edges on both pieces of Cordura.

After trimming the grosgrain tape be sure to heat seal the ends as they can unravel just like the Cordura or webbing.

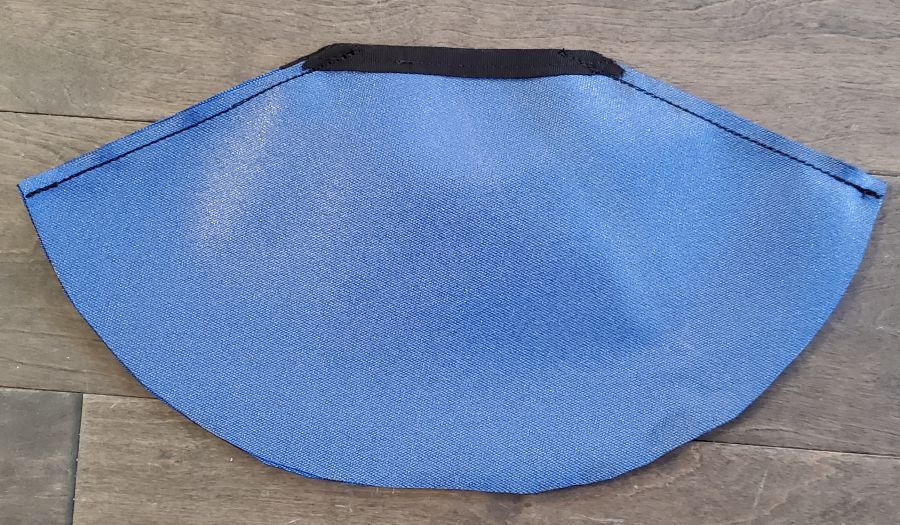

Stitch the

two halves of the Body together with the Right Sides of the fabric together.

Remember to have the right sides (the pretty face of the fabric) of the fabric

facing each other. Place the stitching 9mm (9mm seam allowance) in from the

edge. Stitch down this line two times on each edge. It is good

practice to stitch twice down any seam that needs to be strong. Again its a

little thing that actually makes a difference in the long run. It is difficult

to see in the image since my threads stitched lines are right on top of each

other, but there are actually two stitched lines down each side.

Stitch the

two halves of the Body together with the Right Sides of the fabric together.

Remember to have the right sides (the pretty face of the fabric) of the fabric

facing each other. Place the stitching 9mm (9mm seam allowance) in from the

edge. Stitch down this line two times on each edge. It is good

practice to stitch twice down any seam that needs to be strong. Again its a

little thing that actually makes a difference in the long run. It is difficult

to see in the image since my threads stitched lines are right on top of each

other, but there are actually two stitched lines down each side.

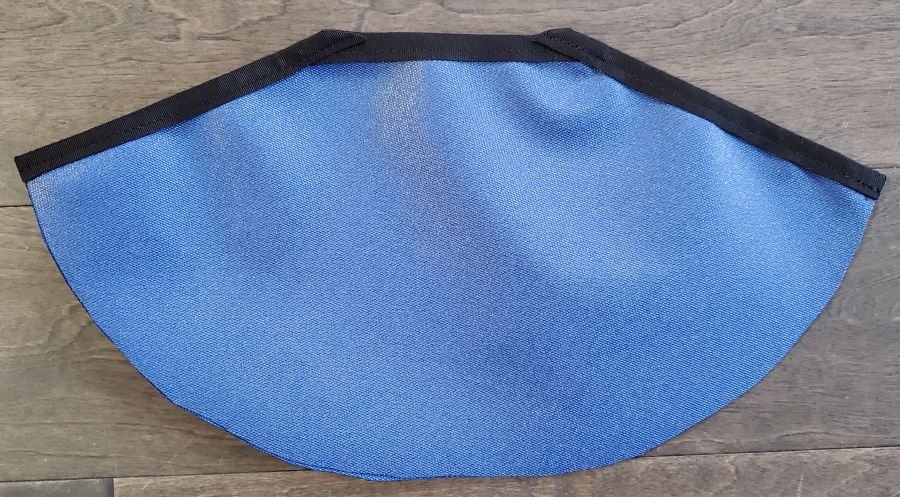

Add grosgrain down both seamed edges. Cut off and heat seal

each end.

Add grosgrain down both seamed edges. Cut off and heat seal

each end.

Fold seamed

edges down and stitch in place. Only one stitch is needed here. You will need

to hold the JellyFish open so you can fold the seamed area down and stitch it

flat. When folding spread and fold the seam all the way to the stitched line.

You will need to stretch and hold short segments at a time to work your way down

the seam as the material fights back.

Fold seamed

edges down and stitch in place. Only one stitch is needed here. You will need

to hold the JellyFish open so you can fold the seamed area down and stitch it

flat. When folding spread and fold the seam all the way to the stitched line.

You will need to stretch and hold short segments at a time to work your way down

the seam as the material fights back.

This is what

the outside looks like with one seam folded flat and stitched down while the

other is not yet folded and stitched. After folding and stitching one

stiched line will be seen on the outside of the JellyFish.

This is what

the outside looks like with one seam folded flat and stitched down while the

other is not yet folded and stitched. After folding and stitching one

stiched line will be seen on the outside of the JellyFish.

Add grosgrain

all the way around outer edge.

Add grosgrain

all the way around outer edge.

When adding the grosgrain to the outer edge, overlap the ends

for clean finish. Remember to heat seal the ends of the

grosgrain after cutting it off.

When adding the grosgrain to the outer edge, overlap the ends

for clean finish. Remember to heat seal the ends of the

grosgrain after cutting it off.

The Body of

the JellyFish is now finished.

The Body of

the JellyFish is now finished.

If all you wanted was a cone hat to wear for a little shade in the

afternoon, you can stop here.

If all you wanted was a cone hat to wear for a little shade in the

afternoon, you can stop here.

Create JellyFish Tentacles

Do the following for both of the pieces of webbing to form two

individual loops. It is important for the loops to be the

same size when finished.

Note:

I do not have a dedicated bartack machine,

so I do my bartacks with my straight stitch machine by going back

and forth a few times. Ideally a true barracking machine would

be used for good strength. For this reason I add more bartacks

than are likely needed to help make the joined area strong.

The join zone in the loops of webbing have also been moved to the

top of the JellyFish to help with strength. By being at the

top the loops are stitched together below the join zone effectively

reinforcing one another. Being at the top also places the join

zones where the least amount of tensile load is placed on them and

the is less abrasion happening. If I true bartack machine were

used the join zone would likely be stronger allowing a different

placement of the join zone in the finished product making it a

little easier to sew. Some of the difficulties in my

particular process arise from working with the relatively stiff join

zone of the webbing loops being placed at the top of the JellyFish.

Make a loop out of each piece of webbing with a 70mm overlap zone.

Make a loop out of each piece of webbing with a 70mm overlap zone.

Be

sure the webbing is not twisted so the loop doesn't have any twists

in it.

In the 70mm

overlap zone......

In the 70mm

overlap zone......

Bartack the webbing 2 times near each end of the overlap zone.

Bartack the webbing 2 times in the center of the overlap zone.

Bartack 1 time between each end and the center bartack.

Sew an X pattern across the overlap zone by stitching from corner(s)

to corner(s)

Attach the JellyFish Tentacles to the Body

This part can be difficult to do as some of the sewing is in tight

areas. You may need to practice a bit to get this done well.

Very important while performing the next steps is to stretch and

hold webbing and body fabric wrinkle free.

Very important to

also keep the body of the JellyFish folded right side out. Resist

the urge to fold it wrong side out for easier access for sewing. If

you fold the body wrong side out while stitching, unfixable wrinkles

will develop in future steps. The wrinkles will be a result of the

fabric being on the outside of the curve (longer distance to travel)

when stitched in place then being on the inside of the curve

(shorter distance to travel) when the body is flipped back to right

side out.

Place join zone of first webbing loop alongside slot and bartack in

place in the center.

Place join zone of first webbing loop alongside slot and bartack in

place in the center.

This is a tight space, be careful not to accidentally

stitch slot together. What you don't see in this image

is the unseen portion of the slot pulled away from the sewing area.

Place join zone of other webbing loop along opposite side of slot

and bartack in place in the center.

Place join zone of other webbing loop along opposite side of slot

and bartack in place in the center.

This is a tight space, be careful not to

accidentally stitch slot together. What you end up with should

look like this. Each webbing loop is bartacked in place at the center

of the slot area with the webbing join zone also centered on the slot area.

Bartack webbing at fabric edge on opposite piece of fabric while

positioning the webbing between the alignment marks made with the pattern.

Bartack webbing at fabric edge on opposite piece of fabric while

positioning the webbing between the alignment marks made with the pattern.

Notice the white dots next to webbing, these are the alignment dots.

Webbing

will angle across the body joining seam and approach fabric edge at

an angle.

Repeat for each of the 4 tentacles so that each one is attached near

the fabric edge.

Before placing the JellyFish in the sewing

machine, the fabric and webbing were stretched tight from center bartack to

fabric edge then squeezed tight to hold the webbing in the correct spot.

If you do not do this you may have a lot of excess wrinkle to deal with.

Note

how each tentacle wraps around the slot and attach to the fabric on the opposite

side.

Note - Important:

Be sure not to have loose end

of the tentacles form a cross over pattern. The end result should

be free hanging loops that do not cross or interfere with one

another. To do this, be sure webbing A crosses over the top of

webbing B on both ends of the slot.

Bartack

webbing to fabric half way between slot and fabric edge.

Bartack

webbing to fabric half way between slot and fabric edge.

Repeat for each of the 4

tentacles.

Bartack both

pieces of webbing to the fabric at

both ends of the slot.

Bartack both

pieces of webbing to the fabric at

both ends of the slot.

You will be stitching through both pieces

of webbing and the fabric.

You will need to push the JellyFish flat

but try not to turn it fully wrong side out.

Do this at both ends

of the slot.

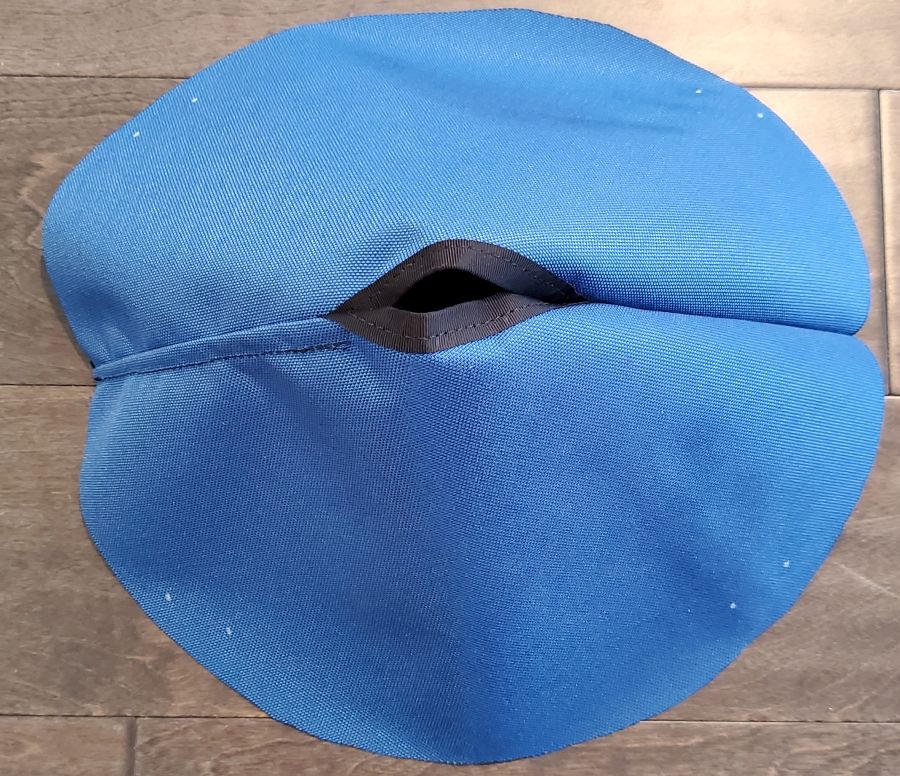

After all 4

tentacles are bartacked.

After all 4

tentacles are bartacked.

Stitch along both sides of webbing from fabric

edge to the slot.

Go all the way up through where the webbing loops cross over.

Near the end of the stitch you will also be stitching

through 2 layers of webbing and the fabric.

Do this for all 4 tentacles

When finished

your JellyFish should look like this. Note that the tentacles are not

crossed and do not interfere with one another in any way. If your are

crossed you overlapped the loops the wrong way up by the slot.

When finished

your JellyFish should look like this. Note that the tentacles are not

crossed and do not interfere with one another in any way. If your are

crossed you overlapped the loops the wrong way up by the slot.

Your JellyFish is complete. Or you could just use it as a hat

with wind straps.